In the dynamic world of commercial kitchens, where efficiency meets culinary artistry, the right equipment can redefine your offerings. For PaniniPro.vn, positioning itself as the premier authority and supplier of Panini Press solutions, understanding the nuances of the Commercial Panini Grill Press is paramount. This robust appliance isn’t just about making sandwiches; it’s a strategic investment that can elevate your menu, streamline operations, and ignite a passion for perfectly grilled food.

Why a Commercial Panini Grill Press is Indispensable for Your Business

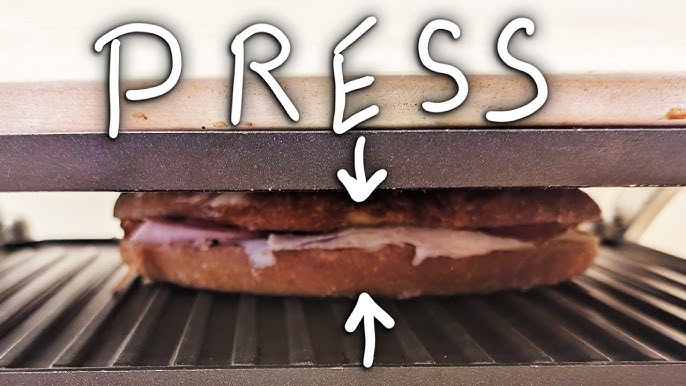

Imagine a bustling café, a vibrant deli, or a busy restaurant kitchen. In these environments, speed, consistency, and quality are non-negotiable. A dedicated commercial panini grill press stands as a workhorse, designed to handle high-volume demands with remarkable ease. Unlike conventional ovens or stovetop methods, these heavy-duty units apply heat and pressure simultaneously from both sides, dramatically reducing cooking times while imbuing sandwiches with that coveted crispy exterior and delightfully melted interior. This dual-action cooking capability means faster service, happier customers, and a more efficient workflow for your team. It’s an indispensable tool for expanding your menu and enhancing customer satisfaction without demanding a complete kitchen overhaul.

The Culinary Journey: A Brief History of the Panini Press

The panini, meaning “little breads” in Italian, started its humble journey as simple grilled sandwiches popular in Italy. These delightful creations found their way across the Atlantic, particularly gaining immense popularity in New York City’s fast-paced culinary scene. What began as a modest pressing method has evolved into a sophisticated grilling technique, inspiring the development of the modern commercial panini grill press. Today, this appliance is a global staple, allowing establishments to quickly serve gourmet, pressed meals that resonate with modern diners seeking quality and convenience.

Deciphering Your Options: Types of Commercial Panini Grill Presses

Choosing the perfect commercial panini grill press means delving into the specifics of its design and functionality. The market offers a range of options, each tailored to different operational needs and menu aspirations.

Single vs. Double Grills: Sizing Up Your Output

The first decision often revolves around capacity: single or double grills. Single panini presses are compact, making them ideal for smaller cafes, coffee shops, or operations with moderate demand, typically producing 20-75 sandwiches daily. They conserve precious counter space and are cost-effective for businesses just starting their panini journey. Conversely, double panini grills are built for high-volume establishments like busy delis or fast-casual restaurants, capable of churning out 100-300+ sandwiches per day. These units often feature two independent cooking zones, allowing you to prepare different items at varying temperatures simultaneously, effectively doubling your production without doubling your footprint. This versatility is crucial for managing peak hours and diverse menu offerings.

Plate Power: Grooved, Smooth, and Combination Surfaces

The cooking surface significantly impacts the final product’s appearance and texture.

- Grooved/Ridged Plates: These are the quintessential panini plates, creating those iconic parallel grill marks that customers associate with freshly cooked, artisanal sandwiches. They also aid in fat drainage, which can prevent sogginess, making them perfect for items with high-fat proteins.

- Smooth/Flat Plates: Offering full surface contact, smooth plates ensure even browning across the entire food item. They are ideal for delicate breads that might tear on ridges, breakfast sandwiches, grilled cheese, quesadillas, or items like hamburgers and French toast where uniform searing is preferred over grill marks. They are generally easier to clean than their grooved counterparts.

- Combination Plates: For ultimate versatility, some commercial grills offer a combination of grooved and smooth plates, or even interchangeable plates, allowing you to adapt to diverse menu applications as needed.

Material Matters: Choosing the Right Plate for Performance and Longevity

The material of your grill plates profoundly affects heat retention, cooking consistency, and durability.

- Cast Iron: The most common choice for commercial units, cast iron plates are renowned for their exceptional heat retention and even heat distribution. While they take longer to preheat, they maintain a consistent temperature, making them perfect for continuous, heavy-duty use. With proper seasoning and maintenance, cast iron can also become remarkably stick-resistant and last for many years.

- Aluminum: A more economical option, aluminum plates heat up quickly and offer rapid heat recovery, making them suitable for intermittent use or operations where speed is a top priority. However, they tend to lose heat faster than cast iron and may require the use of release sprays or oils.

- Vitroceramic/Glass: These advanced plates utilize both radiant and contact heat, leading to impressively fast preheating (often just 3 minutes) and cooking times. Vitroceramic plates are highly durable, scratch-resistant, and incredibly easy to clean, requiring minimal maintenance. They represent a premium choice for high-end establishments prioritizing efficiency and easy upkeep.

- Stainless Steel: While not typically used for the plates themselves due to its heat retention characteristics, stainless steel is a popular choice for the exterior construction of a commercial panini grill press. A stainless steel panini press offers excellent resistance to corrosion, impact, and high temperatures, ensuring longevity and a sleek, professional appearance that stands up to the rigors of a commercial kitchen. It’s often favored for its hygienic properties and ease of cleaning, complementing the functional excellence of internal cooking plate materials like cast iron or vitroceramic.

Key Features That Elevate Your Commercial Panini Experience

Beyond the basic types, several key features distinguish an good commercial panini grill press from an exceptional one, enhancing usability, safety, and performance.

Precision Control: Temperature and Timers

In a professional setting, consistency is king. Look for models with adjustable thermostats, often ranging from 120°F to 570°F, allowing precise temperature control for diverse recipes, from lightly warming tortillas to searing meats. Digital controls take this a step further, offering exact temperature displays and programmable presets, which significantly reduce operator error and ensure uniform results across multiple shifts. Integrated timers, whether mechanical or electronic, are equally invaluable in a busy kitchen, enabling staff to set precise cooking durations and multitask without worrying about overcooking.

Flexibility in Every Press: Floating Hinges and Adjustable Heights

One of the most critical features for a commercial unit is a floating hinge or an adjustable top plate. This ingenious design allows the top plate to pivot and self-level, accommodating sandwiches of varying thicknesses—up to 3 inches in many cases—without crushing delicate fillings or leaving uncooked spots. This ensures even compression and consistent cooking, preventing smashed sandwiches and allowing for a wider range of menu items, from thin wraps to hearty, stacked creations.

Built to Last: Durability and Safety Standards

A commercial panini grill press is an investment, and its durability is paramount. Units constructed with sturdy materials like stainless steel for the exterior and robust hinges are designed to withstand constant use in demanding environments. Safety features are equally important, including cool-touch or ergonomic handles that protect staff from burns, indicator lights to signal readiness, and automatic shut-off functions for peace of mind. Always verify that the equipment meets commercial foodservice standards such as NSF certification for food safety and ETL/UL listings for electrical safety.

Beyond the Bread: Innovative Usage and Recipes for Your Panini Press

While the panini sandwich is its namesake, a commercial panini grill press is a surprisingly versatile piece of equipment, capable of expanding your menu far beyond its traditional role.

The Classics: Perfecting Panini Sandwiches

For the ultimate panini, selecting the right bread is key. Sturdier options like ciabatta, focaccia, or sourdough hold up best under pressure, ensuring a crisp exterior without becoming soggy. Layering ingredients strategically—placing cheese near the bread to act as a “glue” and evenly distributing fillings—helps achieve a balanced flavor and texture.

For a twist on a beloved Italian classic, try a Caprese Panini:

- Brush ciabatta bread with olive oil.

- Layer fresh mozzarella slices, ripe tomato, and fragrant basil leaves.

- Season lightly with salt and pepper, then press until the cheese is beautifully melted and the bread is golden.

Or consider a hearty Chicken Saltimbocca Panini:

- Pound thin chicken cutlets, season, and top with prosciutto and a sage leaf.

- Grill until cooked through, then serve on a roll with sliced fontina cheese.

Unexpected Delights: Grilling Beyond Traditional Panini

Don’t limit your commercial panini grill press to just sandwiches. Its dual heating plates and pressing action make it ideal for a host of other culinary creations:

- Quesadillas: Achieve perfectly melted cheese and crispy tortillas without flipping.

- Omelets: Whisk eggs with your favorite fillings, pour onto the lightly greased press, and gently close for a quick, fluffy omelet.

- Crispy Bacon: Lay bacon strips flat on the preheated press and cook until perfectly crisp.

- Grilled Vegetables: Quickly grill zucchini, bell peppers, or asparagus for healthy sides or sandwich additions.

- French Toast: Dip bread in an egg mixture, then press until golden brown.

- Dessert Panini: Try a decadent Nutella and banana panini on brioche or a sophisticated brie, berries, and honey combination.

Chef Elena Rossi, a seasoned culinary expert in commercial kitchen design, advises, “A panini press is truly an unsung hero. We often see kitchens unlock incredible menu creativity simply by experimenting with how they utilize its unique pressing and heating capabilities. Think outside the sandwich box, and you’ll find endless possibilities for quick, delicious, and visually appealing dishes.”

Keeping Your Grill in Pristine Condition: Maintenance and Cleaning Essentials

Regular maintenance is vital for ensuring the longevity, optimal performance, and hygiene of your commercial panini grill press. Neglecting cleaning can lead to carbon buildup, uneven heating, and even safety hazards.

Daily Rituals for Longevity

After each use, once the unit has cooled to a warm temperature but isn’t scorching hot, begin your daily cleaning routine.

- Unplug for Safety: Always disconnect the power before cleaning.

- Remove Loose Crumbs: Use a grill brush or scraper to gently remove any loose food particles or crumbs from the plates and grooves.

- Steam Clean (Optional but Recommended): For baked-on residue, place a thoroughly soaked, clean cloth or paper towel on the warm plates and close the lid for about five minutes. The steam will help loosen stubborn grime.

- Wipe Down: Use a damp cloth with warm, soapy water to wipe down the plates. Avoid using cold water on hot plates, as this can cause warping or damage.

- Clean Drip Tray: Remove and wash the drip tray with warm, soapy water, ensuring it’s completely dry before reinserting.

- Exterior Wipe: Clean the exterior of the unit with a damp cloth to remove any splatters or grease.

Deep Cleaning for Stubborn Messes

For more stubborn grease or food buildup, a baking soda solution can work wonders (two tablespoons of baking soda mixed with half a cup of warm water). Apply it to the plates, let it sit for 5-10 minutes, then scrub gently and wipe clean. For cast iron plates, re-seasoning periodically after deep cleaning is crucial to maintain their non-stick properties and prevent rust. Lightly coat the cooking surfaces with cooking oil and heat briefly. Avoid harsh abrasive cleaners or metal utensils, especially on non-stick coatings, as these can cause damage and shorten the lifespan of your plates. To further minimize cleanup, consider using heat-safe parchment paper during cooking.

Expert Insights on Panini Press Care

“Maintaining your commercial panini grill press is not just about cleanliness; it’s about preserving performance,” states Marcus Thorne, a commercial kitchen equipment specialist. “Regular cleaning prevents carbon buildup, which directly impacts heat transfer and can lead to unevenly cooked food. A little care goes a long way in extending the life of your investment and ensuring every panini comes out perfectly.”

The PaniniPro.vn Advantage: Elevating Your Brand and Menu

The commercial panini grill press is more than just another piece of kitchen equipment; it’s a tool for culinary innovation and business growth. By offering premium panini service, you can command higher menu prices, while the faster cook times improve table turnover and labor efficiency. A quality commercial grill, with proper maintenance, is a long-term investment, typically lasting 5-10 years. This robust ROI makes it an intelligent choice for any food establishment looking to expand its hot sandwich offerings and diversify its menu with grilled specialties. PaniniPro.vn empowers businesses with the knowledge and products to harness this advantage, turning simple ingredients into extraordinary experiences.

Frequently Asked Questions About Commercial Panini Grill Presses

Q: What’s the main difference between a “panini grill” and a “sandwich press”?

A: Functionally, they both use heated plates to press and cook sandwiches. “Panini grill” usually implies ridged plates for grill marks, while “sandwich press” can refer to units with either smooth or ridged plates. In commercial kitchens, the terms are often used interchangeably.

Q: How many sandwiches can a commercial panini grill produce per hour?

A: A standard single commercial panini grill (around 14″ width) can typically produce 10-15 sandwiches per hour. Double grills can double this output to 20-30 per hour, with larger models reaching up to 40 per hour depending on cook time and heat recovery.

Q: Do I need special electrical wiring for a commercial panini grill press?

A: Compact and standard single grills often run on standard 110V/15-20 amp circuits. However, large single grills and double grills usually require dedicated 208-240V circuits and professional installation. Always check the manufacturer’s specifications.

Q: Can I use a panini grill for items other than sandwiches?

A: Absolutely! Commercial panini grill presses are incredibly versatile. They can effectively cook quesadillas, flatbreads, various vegetables, chicken breasts, burgers, bacon, and even certain fruits or sweet treats.

Q: What’s the best way to prevent food from sticking to the grill plates?

A: Ensure the plates are fully preheated to the correct temperature before placing food. Lightly butter or oil the exterior surfaces of your bread or food items. Keeping non-stick coatings in good condition and regularly cleaning the plates to prevent residue buildup are also crucial steps. For cast iron plates, proper seasoning is key.

Q: How long should I preheat my commercial panini grill press?

A: Allow 10-15 minutes for the plates to reach and stabilize at the target temperature (typically 350-375°F). Under-preheating can lead to longer cooking times and uneven browning. Rely on indicator lights or an infrared thermometer to confirm readiness.

Q: How do I maintain those perfect grill marks?

A: For consistent grill marks, use ridged plates and ensure even pressure across the food. Preheat the grill fully and avoid shifting items once they are placed. Regular cleaning of the grooves is also essential to prevent residue from interfering with contact.

The Final Press: Your Path to Panini Perfection

The commercial panini grill press is more than just an appliance; it’s a gateway to culinary innovation and operational excellence for your business. From the speed it brings to service to the versatility it adds to your menu, its benefits are clear. By understanding the types, features, and best practices for care, you can choose the ideal grill to meet your demands, ensuring that every pressed creation delights your customers. Embrace the power of the panini press, and let PaniniPro.vn be your guide to achieving panini perfection and a thriving online presence.